24-hour hotline:+8613662168047

Keyword search: battery plant , lithium battery factory , power bank works , lifepo4 battery mill , lithium forklift battery manufacturer

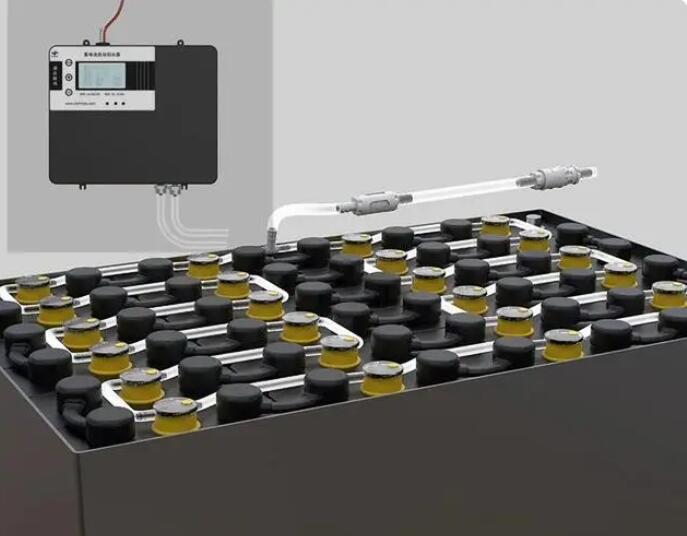

In the past two years, with the skyrocketing oil prices and the continuous improvement of emission standards for internal combustion forklifts by the country, everyone has focused on battery forklifts. With the passage of time, the use of electric forklifts has become increasingly popular. Today, let's talk about the precautions for using forklift batteries. There is no one size fits all strategy for forklift electricity. Every enterprise has its own solution, and warehouse capacity, operational details, scale, budget, environmental and safety issues, as well as time constraints, are important factors in making the ultimate decision. Today, the editor will share with you the types of forklift batteries and solutions to extend battery life.

1、 Lithium batteries for forklifts

There are two main types of lithium batteries for forklifts: nickel manganese cobalt oxide (NMC) batteries and lithium iron phosphate batteries. The advantages and disadvantages of each type vary depending on the application, but generally speaking, lithium-ion batteries have the following characteristics:

(1) Cost

The initial cost of lithium-ion batteries is higher than other battery technologies. That is to say, with the development of technology, prices are decreasing and they do not require any maintenance requirements, which means they may be a cost-effective choice for some high-speed operations. Compared to lead-acid batteries, lithium-ion batteries provide approximately twice the power during their lifecycle, with a total cycle count of approximately 3000 times.

(2) Charging Requirements

If the power system design is optimized, a completely depleted lithium battery can be fully charged and ready within one hour. Unlike lead-acid batteries, the charging process of lithium batteries is extremely efficient and does not generate any significant heat. This allows the battery to continuously charge quickly without any adverse effects on the battery. Unlike lead-acid batteries, lithium batteries do not require weekly balanced charging.

(3) Operating speed

Due to the relatively inefficient charging and cooling process described above, lead-acid batteries can suppress high-speed material handling operations, which we define as two or three shifts. On the other hand, smaller and less frequently used forklift operations are often the preferred choice for lead-acid batteries.

(4) Maintenance

Lithium batteries are essentially maintenance free, providing financial and logistics advantages. However, just like anything with electronic components, it is strongly recommended to perform some maintenance and overall fleet management to optimize the lithium-ion power system.

(5) Security

Lithium batteries designed for forklifts are usually very safe to use because their chemical composition is much more stable than some other lithium chemical components you may have heard of. However, a vehicle mounted intelligent management system is needed to separately monitor each battery and ensure that there are no imbalances or overheating issues. At extreme temperatures, thermal runaway can lead to lithium fires that are difficult to extinguish. Due to the complex internal control system, these accidents are extremely rare and are standard equipment for almost all lithium batteries in the material processing market today.

(6) Environment

Although lithium-ion batteries are recyclable, the cost of doing so is much higher than lead-acid; Therefore, it is difficult to find facilities for recycling them, and some lithium battery manufacturers also charge fees for the recycling of old lithium batteries. On the positive side, once lithium batteries degrade to a level that may not be meaningful in the expected application, they can still play a role in other applications, such as backup power. With lithium ions becoming a modern solution for transportation electrification, significant progress in the recycling process is inevitable.

2、 Thin plate pure lead battery (TPPL)

Thin plate pure lead battery (TPPL) is an advanced absorbing glass mat (AGM) battery. In terms of performance and capacity, they are an enhanced version of lead-acid technology that requires less maintenance.

1. Cost

TPPL batteries are about 30% more expensive than lead-acid batteries, but their initial cost is lower than lithium-ion batteries. The expected lifespan of TPPL batteries is two (2) to four (4) years, which also depends on many specific application variables.

2. Charging

The charging speed of TPPL batteries is much faster than that of standard lead-acid batteries, but not as fast as lithium-ion batteries. A key issue to remember when using TPPL technology is that the battery can only discharge to around 40% before warranty failure. Therefore, the ideal application of TPPL technology is the operation of having a large number of opportunities to insert chargers. The deeper the discharge of TPPL batteries between two charges, the lower their expected lifespan. In fact, most TPPL batteries have an onboard alarm system that notifies the operator when charging is required. Although the charging efficiency of using TPPL batteries is significantly better than using lead-acid at around 85%, it is a less efficient process compared to using lithium-ion batteries.

3. Maintenance

TPPL batteries do not require watering or weekly balancing like lead-acid batteries. However, they do need to be fully charged at least once a week and regularly checked for battery imbalance. Unlike standard lead-acid batteries, TPPL batteries have a very low self discharge rate, allowing for long-term fully charged storage without any adverse effects on the battery.

4. Running speed

TPPL batteries are a great solution for single or two shift manufacturing industries with light to medium usage, where production or interruption plans allow for frequent blockages, but they may not be a comprehensive solution for high-speed operations. In higher demand applications, the main limiting factor of TPPL batteries is the inability to discharge these batteries to below 40% State of Charge (SOC).

5. Elasticity

Compared with traditional lead-acid batteries, TPPL models have much higher elasticity in terms of heat and cold, but extreme heat and cold should still be avoided. Repeated excessive discharge can also lead to premature battery failure.

6. Security

TPPL batteries are as safe as lead-acid batteries, and in many cases, they are safer than lead-acid batteries. This is because TPPL batteries are designed for opportunistic or fast charging (without the need for battery replacement) and effective maintenance free.

7. Environment

Similar to lead-acid batteries, TPPL batteries are almost 100% recyclable. TPPL batteries also have near zero gas emissions.

Forklift batteries come in various shapes and types. Although these hazards are quite common for all types of lead-acid batteries, there may be other or unique hazards specific to the type of battery used.

Forklift and power industrial vehicle manufacturers typically provide training and information at little or no cost to help employees and supervisors operate and maintain their equipment safely and effectively. Please make sure to take advantage of this and have workers receive training on proper storage and charging of forklift batteries to help ensure employee safety, comply with regulations, and avoid fines.

In summary, industrial lithium battery manufacturers are an important component of forklifts, providing the power required to operate vehicles and their various systems. There are several different types of industrial forklift batteries, including lead-acid, nickel cadmium (NiCd), and lithium-ion batteries, each with its unique characteristics. Industrial forklift batteries require regular maintenance to ensure their optimal operation, and it is important to follow the correct safety guidelines when handling and charging. The cost of industrial forklift batteries may vary greatly depending on the type and size of the battery, as well as the manufacturer. It is important to consider the upfront cost of the battery as well as the long-term cost of maintenance and replacement to determine the most cost-effective option.

Lithium ForkLift Batteries ,Ensure Quality

Our lithium battery production line has a complete and scientific quality management system

Ensure the product quality of lithium batteries

Years of experience in producing lithium forklift batteries

Focus on the production of lithium batteries

WE PROMISE TO MAKE EVERY LITHIUM BATTERY WELL

We have a comprehensive explanation of lithium batteries

QUALIFICATION CERTIFICATE

THE QUALITY OF COMPLIANCE PROVIDES GUARANTEE FOR CUSTOMERS

MULTIPLE QUALIFICATION CERTIFICATES TO ENSURE STABLE PRODUCT QUALITY

Providing customers with professional and assured products is the guarantee of our continuous progress.

Applicable brands of our products

| Linde Lithium Forklift Battery | Toyota Lithium Forklift Battery | hyster Lithium Forklift Battery |

| jung Lithium Forklift Battery | enrich Lithium Forklift Battery | hyundai Lithium Forklift Battery |

| still Lithium Forklift Battery | heli Lithium Forklift Battery | hangcha Lithium Forklift Battery |

Service hotline

Service hotline