24-hour hotline:+8613662168047

Keyword search: battery plant , lithium battery factory , power bank works , lifepo4 battery mill , lithium forklift battery manufacturer

The main goal of the lithium iron phosphate industry in 2024 is to reduce costs.

Cost reduction background

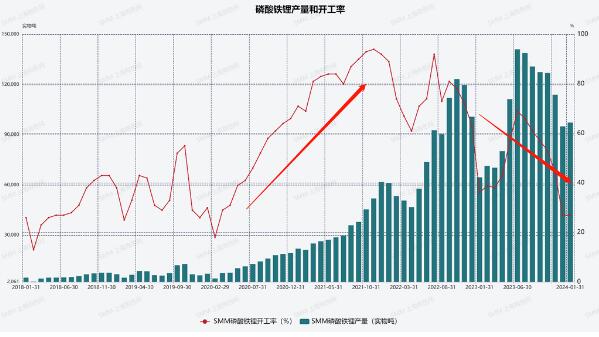

With the expansion of the lithium iron phosphate industry, its development rate has narrowed. In the lithium iron phosphate industry, production capacity rapidly increased from the second half of 2021 to 2023; Starting from the end of 2022, when the national subsidy for new energy vehicles is declining, and the window for capacity expansion continues to open, the operating rate of lithium iron phosphate remains around 50%, or even less than 30%.

Changes in operating rate of lithium iron phosphate

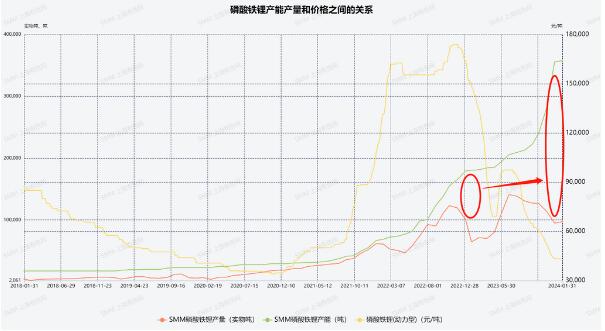

Starting from Q4 2022, the gap between production capacity and output has widened, and new production enterprises are continuously releasing their production capacity, resulting in an overall low operating rate in the lithium iron phosphate industry. In the context of overcapacity and slowing demand growth, iron lithium enterprises seize the market at low prices to maintain market share, and battery cell enterprises also use low prices as the entry threshold for new suppliers.

The relationship between production capacity and price of lithium iron phosphate

The price of lithium iron phosphate has declined, and enterprises have entered a state of loss from profitability. In the future, as the demand for lithium iron phosphate slows down, the production of lithium iron phosphate will maintain a relatively low growth rate.

Changes in production of lithium iron phosphate (2018-2027F)

With overcapacity, slowing growth in new demand, the wool of capital still remaining in the lithium iron phosphate industry, and leading enterprises maintaining absolute dominance in industry negotiations, the industry's growth rate has narrowed, and profits have also narrowed.

Based on the above factors, the industry has entered a new stage of development: reducing costs and increasing efficiency!

Cost reduction process

Reducing costs and increasing efficiency is the future development trend of the lithium iron phosphate industry. In the crowded race track of the industry, enterprises are forced to reduce costs in order to adapt to the pace of the track.

In the lithium iron phosphate industry, the cost reduction and efficiency increase of the two giants are achieved by forcefully squeezing the profits of upstream suppliers.

1. Lithium carbonate raw materials: Giant enterprises have put effort into lithium carbonate, one of the main raw materials of lithium iron phosphate, by investing in, acquiring, mining, and purchasing lithium raw materials through large orders and long-term agreements, in order to control the discourse power of resources and market negotiations. The profit of lithium carbonate raw materials is being squeezed, which forces the profit of lithium ore resources to be squeezed.

2. Other raw materials: Giant enterprises implement individual breakthroughs in the price system of supplier supply through bidding or individual negotiations. Enterprises that can squeeze into the new energy market have some financial resources, and giant companies will give limited procurement to those willing to supply at low prices, thus gaining a second hand. The price of lithium iron phosphate is being squeezed upwards, squeezing iron phosphate raw materials, phosphorus raw materials, carbon sources, and so on.

3. Land and population: Cost reduction ultimately comes down to land and population. All cost reduction efforts are pushing towards mineral resources, tilting towards areas with low energy consumption and low costs, and moving towards enterprises with low labor costs and high levels of automation.

Cost reduction risk

The two giants are leading each other's cost reduction efforts, and the lithium iron phosphate market has begun a round of cost reduction competition, causing prices at various supply ports to be suppressed. Cost reduction has evolved into a process of "starving for survival" for various suppliers. While surviving, there will be continuous production capacity being cleared, and the lithium iron phosphate track will gradually shift from crowded and chaotic to orderly.

The two giants have the capital to reduce raw material suppliers: firstly, there is a high demand; secondly, payment terms are strict but payment can be made on time; thirdly, entering their supplier system means that product quality is excellent.

Cost reduction may disrupt the stable supply chain system and add many unstable factors. Although it is a slow change, it still adds risks to the future.

Cost reduction may lead to a shift in capital investment direction and a re examination of the current lithium iron phosphate industry. More cautious in investment, may be more friendly to monopolistic and highly competitive enterprises, and pay less attention to ordinary newly joined enterprises.

Finally, where did the cost reduction go? Who will benefit from the cost reduction? The profits of the entire society have still fallen into the pockets of a downstream customer. This is a thought-provoking question.

Lithium ForkLift Batteries ,Ensure Quality

Our lithium battery production line has a complete and scientific quality management system

Ensure the product quality of lithium batteries

Years of experience in producing lithium forklift batteries

Focus on the production of lithium batteries

WE PROMISE TO MAKE EVERY LITHIUM BATTERY WELL

We have a comprehensive explanation of lithium batteries

QUALIFICATION CERTIFICATE

THE QUALITY OF COMPLIANCE PROVIDES GUARANTEE FOR CUSTOMERS

MULTIPLE QUALIFICATION CERTIFICATES TO ENSURE STABLE PRODUCT QUALITY

Providing customers with professional and assured products is the guarantee of our continuous progress.

Applicable brands of our products

| Linde Lithium Forklift Battery | Toyota Lithium Forklift Battery | hyster Lithium Forklift Battery |

| jung Lithium Forklift Battery | enrich Lithium Forklift Battery | hyundai Lithium Forklift Battery |

| still Lithium Forklift Battery | heli Lithium Forklift Battery | hangcha Lithium Forklift Battery |

Service hotline

Service hotline